How I reduced time on task by 62% while minimizing development effort

The Problem

Missing a key feature for cost engineers prevented adoption of aPriori cloud software

Cost engineers are responsible for bulk costing

CAD Assembly

-

Cost engineers at our customers’ manufacturing company are responsible for costing multiple parts in an assembly all at once to identify cost reduction opportunities

What aPriori offered didn’t satisfy the needs of cost engineers

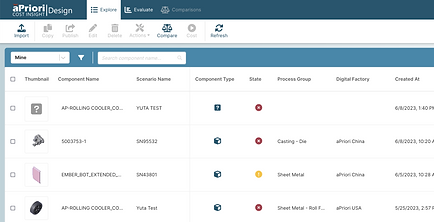

aPriori cloud costing simulator

-

While aPriori’s multi-tenant cloud software has cost simulation capability, it lacked the capability to cost multiple parts at the same time

-

This meant none of the cost engineers were adopting aPriori’s cloud software

aPriori decided to add bulk costing capability on cloud platform aiming to increase adoption by 25%

Overview

My Role

-

Design bulk costing capability on the cloud software to increase adoption

Responsibilities

-

Understanding requirements and designing a solution meeting user needs

-

Collaborating with other stakeholders

-

Involving other stakeholders in UX process and aligning on design solution

Stakeholders

-

UX Manager

-

Cross-department PMs

-

Software Engineers

-

Software Architects

Gathering requirements from stakeholders

Preliminary discussions with the stakeholders revealed time and resources were limited

-

Bulk costing is one of time-sensitive priority features

-

Time to market was important to meet the need of customers who wanted cost engineers to use cloud solution as well

-

Enhancing cloud platform is part of an ongoing initiative to migrate out of expensive on-premise platform

-

-

Limited resources

-

Additionally, only two engineers and one architect were dedicated for bulk costing project

-

-

This required us to contain scope and minimize development effort

Defining scope and requirement to launch a minimal viable solution

-

Since the project managers from different departments have previously interviewed our customers’ cost engineers, they understand cost engineers’ current workflow

-

I conducted three rounds of workshops with the PMs to ensure I captured cost engineers’ existing workflow and identify key steps needed in the solution

-

Key steps in the workflow needed for version 1:

-

Importing parts (CAD files) and storing them in a container

-

Setting inputs for similar parts

-

Costing every parts after inputs are set

-

Coming back to the container to iterate on costing

-

Designing the key steps using existing components

-

In addition to defining and minimizing scope, my focus was to reduce development effort by using existing components wherever possible for my design

-

This way the engineers can reuse what’s in the product already to reduce time to market

1

Importing parts and storing them in a container

Current

-

The existing application has a dialog for users to import CAD files

-

However users cannot store them in a specific container

Existing dialog used for importing CAD files

New

-

I enhanced the dialog by adding the ability to store CAD files in a specific bulk costing project (worksheet)

My design with dropdown added

2

Invoking actions necessary for bulk costing

Current

-

Action bar is used to invoke different actions related to the parts selected

Action bar in existing application

New

Actions for bulk costing

-

I reused this component and added critical actions needed for bulk costing like "Set Inputs" and "Cost"

-

Cost engineers can select components they want to set inputs for and click on "Set Inputs" button to bulk edit the parts

3

Setting inputs for similar parts

Current

-

That will invoke the "Set Inputs" dialog

-

Existing dialog can edit inputs but it cannot save information without costing the parts

Existing dialog that sets inputs and cost

.png)

New

-

I reused this dialog but changed the CTA from “Cost” to “Save” to allow users to first set the inputs before costing all parts

New dialog that only sets inputs

4

Initiating bulk costing

New

-

Once they are done setting inputs for everything, they can click on the “Cost Uncosted Scenarios” button to invoke bulk costing and go work on other tasks until costing is done

5

Coming back to bulk costing container

Current

-

Table component is already used to display different groups of parts in another feature

Existing table in the application

New

-

I decided to follow the same pattern by using the table component to display different bulk costing projects

-

Having a table allowed users to store parts in groups and to come back to it when costing is done

Table reused in bulk costing

Usability testing with four cost engineers

Users can import CAD files but they were lost on the next steps

-

After importing CAD files, users were left on bulk costing screen with no clear instruction leaving the users confused

Furthermore, there were too many ways to bulk cost, making the users unsure which option to choose from

-

Having two options to set inputs confused users

-

While the original intention was to retain existing costing functionality, users' expectation was to only set inputs

-

Users were surprised to see a dropdown with two different costing options

-

Rather than having flexibility in costing, users expected to simply click on a cost button and cost all parts

We needed a more concrete process for users to follow based on their expectation

-

Upon discussing the results with the stakeholders, I gained their buy-ins to pivot our solution

Step-by-step instruction to guide the users through the process

-

In order to setup a more concrete process for the users to follow, I added cards at the top of the page instructing users how they can bulk cost

Old

New

Old

-

Furthermore, key actions like “Set Inputs” and “Cost” were simplified to avoid ambiguity

-

All costing buttons are simplified to “Cost All” button instead of providing different choices

-

"Set Inputs" button has closer proximity to the parts helping with discoverability of key action

New

-

However, the design was still kept simple for engineers to code

-

While we could introduce more robust wizard capability, that would add more engineering effort making it out of scope for this project

The Result

Minimal effort with high impact

Current Bulk Costing Workflow

-62%

New Guided Workflow

-

Cost engineers were spending around 3 minutes 15 seconds to conduct one bulk analysis but my design was able to reduce it down to 1 minute 16 seconds, achieving 62% reduction in time on task

-

However, design was kept simple to contain scope and for software engineers to implement the design in time